Ultra Sensors

Food production is an overall careful process that requires close monitoring of environmental conditions at practically every level. Temperature, humidity, and water leakage are all factors that need to be monitored and controlled during storage, processing, and transportation processes, and having precise monitoring equipment can make all the difference in maximizing profits and minimizing both product quality issues and consumer safety issues.

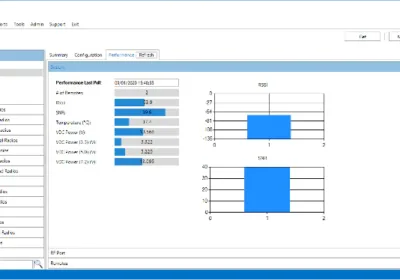

ULTRA Sensors are a great solution to all of these potential issues. The ULTRA temperature, humidity, and water detect sensors, along with the Device Endpoint Management (DEM) software are a powerful ensemble of tools that help ensure the highest quality, safe end product for the consumer.

ULTRA Temperature Sensors

Temperature monitoring and control are crucially important in proper refrigeration storage for raw and pre-preparation food storage, as well as for the preparation, storage, and shipping of final food products. In the former, different food stocks will warrant different preferred storage temperature ranges. Wrapped meats, for example, should be stored between 28˚F and 32˚F. Vegetables might be stored between 32˚F and 39˚F in cold storage, or 40˚F and 50˚F in moist storage. With final food products, in the latter case, there are also important temperature considerations. French fries, for example, should be fried at 335˚F, while vegetables should be fried at 165˚F. For transportation, these ranges increase drastically, as hot food transport will typically stay above 140˚F, while cold food might need to be stored as low as subzero temperatures.

Keeping track of all of these vastly different and specific temperature specifications can certainly be a lot of tedious work. Luckily, ULTRA Temperature Sensors automate this process. Sensors can be placed in different locations based on food type and desired temperatures, and they can be set to automatically identify out-of-range temperatures and signal an alert before the product becomes contaminated. Sensors can also be placed in vats, production environments, storage, and transportation units to ensure that temperature fluctuation is minimized at every step of the process, making sure that top quality food is always delivered to consumers.

ULTRA Humidity Sensors

Temperature is an undeniably important factor to monitor to ensure the best food quality possible, but it certainly isn’t the only factor to keep in mind. Humidity is another vitally important factor. Proper humidity control in food preparation environments will help minimize food rot and poor quality throughout the different storage processes. Vegetables, for example, should be stored at 95% humidity, while grains should be stored at less than 14% humidity.

Just as with the temperature sensors, ULTRA Humidity Sensors can be placed in all food storage, preparation, and transportation environments to ensure proper humidity levels are maintained throughout the entire food production process. Proper humidity control is another important factor in minimizing contamination, rot, and poor food quality.

ULTRA Water Detect Sensors

Temperature and humidity control are perhaps the most important facets of quality food production, but both temperature and humidity can take a rapid turn out of control when unwanted or harmful water is introduced. Being able to quickly detect harmful water presence is vital in sensitive food storage, preparation, and transportation environments. Detecting water quickly and efficiently can also help minimize dangerous work conditions and other potential harm to both the quantity and quality of the final product.

To protect against these risks, ULTRA Water Detect sensors can be placed in all of the same environments to make sure unwanted or harmful water is quickly detected and reported. Rules and alerts centered around leakage are instrumental in making sure production levels are met and customers are satisfied with the final product.

The ULTRA Temperature, Humidity, and Water Detect Sensors, along with the software that brings them all together, allow not only for a careful, holistic, precise monitoring of environmental conditions but also for the rapid response necessary for ensuring the highest possible quality product, making for the best possible profits and the best possible consumer experience.

If you are interested in this solution, contact Scott Allen.

Leave a Reply