E2E Expertise Published in CIO Magazine

Network Management in an IoT World – From Oil Fields to Agriculture

Network management solutions have historically focused on Information Technology servers and network devices. With recent advances in the Internet of Things, the number of devices that can now be managed and monitored has mushroomed. Specifically, the Industrial Internet of Things (IIoT), with a current market size estimate of USD 210 billion and forecast to be over USD 940 billion by 2025,1 will drive the need for advanced management techniques as well as the ability to effectively analyze large amounts of data. The IIoT calls for improved management — an Industrial Management Solution.

“Must Have” Characteristics of a Modern Industrial Management Solution (IMS)

- Vendor agnostic. The software should not be specific to a vendor’s unique equipment, but have the ability to work with multiple vendors’ equipment. This provides the “single pane of glass” that so many vendors tout, but few deliver.

- Visualize end-to-end connectivity. It is crucial to depict the topology of connected devices from the data center or application to the far-end IIoT devices. Networks with multi-homed network paths, cellular connections, and cloud systems make this programmatic depiction a challenge.

- Root-cause correlation. Operation Centers require a management system that avoids multiple alerts for a single issue. Root cause correlation reduces unwanted notifications by pinpointing the problem that needs correction which, in turn, reduces downtime and minimizes costly troubleshooting.

- Automation of new device configuration. Operational cost savings are in abundance when standard device configurations can be replicated during large-scale equipment roll-outs. Reduced device setup times and elimination of configuration mistakes from manual changes result in less truck rolls, reduced trouble-shooting, and consistent configurations. All are time and money savers!

- Bulk configuration changes. Changing a few devices by remotely logging in saves time. But, when a large number of devices are deployed, configuration updates require the ability for bulk operational changes. The ability to make changes in bulk reduces operational costs significantly in both resource time and costly truck-rolls.

The ultimate goal of an Industrial Management Solution is to provide value. Along with the characteristics already described, an IMS provides data and analytics that help customers make better business decisions.

“Must Have” Qualities of Data in Modern Management Systems

- Data should be relevant. Collecting relevant data is best achieved through a micro-collection framework. Within this framework, filters can be used to group devices and provide targeted collections configured specifically for each group. These collections can vary in the depth and type of data collected, as well as the frequency at which the data is collected. This allows critical performance data to be collected more often than configuration data which is more static. This architecture also allows polling parameters to be configured for each micro-collection to match the protocol and/or bandwidth of the endpoints in each collection.

- Data should be timely. Knowing that the temperature of a critical storage facility has dropped too low is not helpful if the sensor reading can’t be delivered in real-time. Having an IMS that can detect and respond to outages quickly keeps critical data flowing.

- Data should be accessible. An IMS should provide a way for customers to quickly query and analyze the data that is being collected. Having lots of big data storage is not valuable if the customer can not access the information quickly and efficiently.

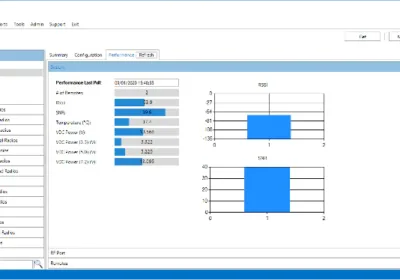

- Data should be visible. An IMS should provide an easy way to visualize and display information that is critical for a company’s operation. A graph or chart isn’t valuable because it looks good; it’s valuable because it makes the data clear and easy to understand.

- Data should be complete. In order to correlate issues or to make informed decisions, the data being collected must be complete. If the signal strength of a wireless device is weak due to a low battery, then both of these pieces of data need to be collected in order to correlate them. For completeness, data should be collected from all devices in the network — from the data center to the edge devices to the sensors

Along with the data, however, a modern Industrial Management Solution should provide an analytics engine that can harness the power of that data. A well designed engine with intelligent rule processing can allow seemingly meaningless pieces of data on their own to be combined with other data that provides valuable information for a customer. In the end, however, the value of the analytics will depend on data that is relevant, timely, accessible, visible, and complete.

In this data-driven world, the ability to collect data and manage the devices and networks that deliver that data is critical to the success of many businesses. A modern Network Management Solution that effectively manages, collects, and analyzes data can be an invaluable tool for success in today’s IoT market.

Our company’s name, End 2 End Technologies, expresses our company’s goal as well — we provide customers with valuable data from end-to-end management of the things that comprise their network ecosystem

Leave a Reply